Advantages:

1. ensure sealing of furnace wall and reduce air leakage in combustion chamber.

2.realize full water cooling of the combustion chamber, which is helpful to prevent coke formation in the case of intensified combustion.

3. small capacity of heat storage, fast heating of combustion chamber and rapid cooling, can shorten the cooling time of boiler start and stop.

4.it is appropriate to use pipe furnace wall, which greatly reduces the load of boiler frame and is convenient for suspension.

5.compared with the optical tube, the heat absorption capacity of the tube is improved.

6.the pre-combination degree of boiler components is improved, which is convenient and reduces the installation workload.

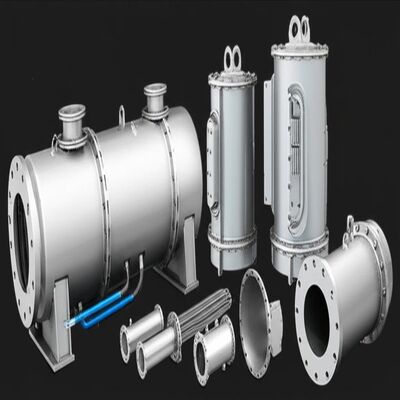

Product Description:

A waterwall in a boiler is any furnace wall that is comprised of refractory and tubes in a water-tube boiler. The tubes are evenly spaced and generally connect to headers which in turn are connected back to the main generating bank of the boiler. They serve a two fold purpose here in that they capture heat that would otherwise escape to the atmosphere and help heat the water in the boiler. And they also help keep the refractory cool.This prevents spalling of the refractory.

Specification:

| Name |

Membrane water panel |

| Material |

Carbon steel,Alloy steel,etc. |

| Tube size |

Φ38 - 76 mm, Customization |

| Standard |

ISO , ASME |

| Model |

Studded |

| Dimension |

Customization |

| Manufacturing process |

Material→Ingot → Hot/Cold-Rolling→ Heat treatment (Normalizing+ tempering) → Inspection →Polishing→Tube joint welding→Assembly →Welding→Inspection→Heat treatment→Hydraulic pressure test→Painting→Packaging |

| Installation location |

Around the boiler combustion chamber |

Usually laid vertically on the inner surface of the furnace wall, it is mainly used to absorb the radiant heat from the flame and high-temperature flue gas in the furnace.It is the main type of evaporative heating surface of modern boiler and also the basic part of water circulation loop of boiler.As a combination of cooling and protective furnace wall.

The water-cooling walls were originally designed not to be heated, but to cool the furnace so that it would not be damaged at high temperatures.Later, as a result of its good heat exchange function, gradually replaced the drum to become the main heating parts of the boiler.

An evaporative heating surface composed of many parallel pipes is arranged on the inner wall of the boiler furnace.The role of the water wall is to absorb the radiant heat of the high temperature flame or flue gas in the furnace, generate steam or hot water in the pipe, reduce the temperature of the furnace wall, and protect the furnace wall.In the large capacity boiler, the flame temperature is very high and the intensity of thermal radiation is very high.The boiler contains 40 to 50 percent or more of the heat absorbed by the water wall.With the exception of a few small capacity boilers, modern water tube boilers use water cooling walls as the main evaporative heating surface.

FAQ:

Q1: How long is the warranty period?

We provide 18 months warranty for all spare parts(exclude fragile parts).

Q2: How can we guarantee quality?

1 All machines are in strict accordance with the ISO quality and CE system requirements.

2 Each procedure is crafted by professional Skilled labour, followed by particular QC

3 All information of our products can be checked in efficient management system.

Q3: What can you buy from us?

Boiler Economizer, Boiler Fin tube, Boiler Air preheater, Boiler superheater, Boiler membrane wall,

Boiler manifold headers and other pressure spare parts.

Q4: What kind of service do you provide?

Before sales:

Provide productinformations, market research forecasting, product customization,product processing,consultation and other services for your convenience.

Q5: Are you a factory or trading company, where are you located?

We are a factory, just 130km(2 hours by car) away from Shanghai Airport.

We offer pickup service at Shanghai for your visit.

Il tuo messaggio deve contenere da 20 a 3000 caratteri!

Il tuo messaggio deve contenere da 20 a 3000 caratteri! Si prega di controllare la tua email!

Si prega di controllare la tua email!  Il tuo messaggio deve contenere da 20 a 3000 caratteri!

Il tuo messaggio deve contenere da 20 a 3000 caratteri! Si prega di controllare la tua email!

Si prega di controllare la tua email!